MUHAMMAD IQBAL

Mechatronics Engineering @ UWaterloo

CAD Design • Embedded Systems • Manufacturing

About Me

I’m a Mechatronics Engineering student at the University of Waterloo with hands-on experience in mechanical design, manufacturing support, and embedded systems. I’ve worked in production-adjacent environments where designs must be manufacturable, toleranced correctly, and clearly documented to succeed outside of CAD.

My engineering approach is analytical and practical. I break problems down, identify constraints, and make decisions based on failure modes, manufacturability, and system-level trade-offs. I’m comfortable working with incomplete information, validating assumptions, and iterating designs based on real feedback from manufacturing and testing.

I bring value to teams by translating requirements into buildable solutions, supporting cross-disciplinary work between mechanical and electrical systems, and thinking critically about how parts and systems will actually be produced, assembled, and used.

I am a second-year Mechatronics Engineering student actively seeking Summer 2026 internship opportunities (May–August 2026).

Motoman HP50 Robotic Forming Cell

Industrial Robot Programming & Production Validation

Robotic Programming & Motion Sequencing

Programmed a Motoman HP50 industrial robot using the INFORM language to automate a multi-step sheet metal forming process. Starting from basic template commands, manually coded motion paths for part pickup, repositioning, press brake loading, and intermediate rotations required to complete a six-bend forming sequence. All robot motion was developed remotely and executed in robot-controlled press brake mode.

Process Integration & Collision Avoidance

Integrated the robot with a press brake operating in robot mode, including signaling for each forming operation. Programmed coordinated pickup and placement using a custom vacuum gripper designed for aluminum parts. Manually defined collision-free paths in a constrained workspace with minimal sensing, requiring careful control of approach angles, clearances, and part orientation throughout the forming cycle.

Production Tuning & Validation

Iteratively tested and refined robot programs on real sheet metal parts, adjusting motion timing, positioning, and sequencing to achieve consistent forming and reliable handling. After initial tuning and approximately 30 trial parts, validated stable operation and allowed the cell to run for ~2000 production parts. Verified final part fit and optimized an alternating floor stacking pattern to maximize space efficiency during output.

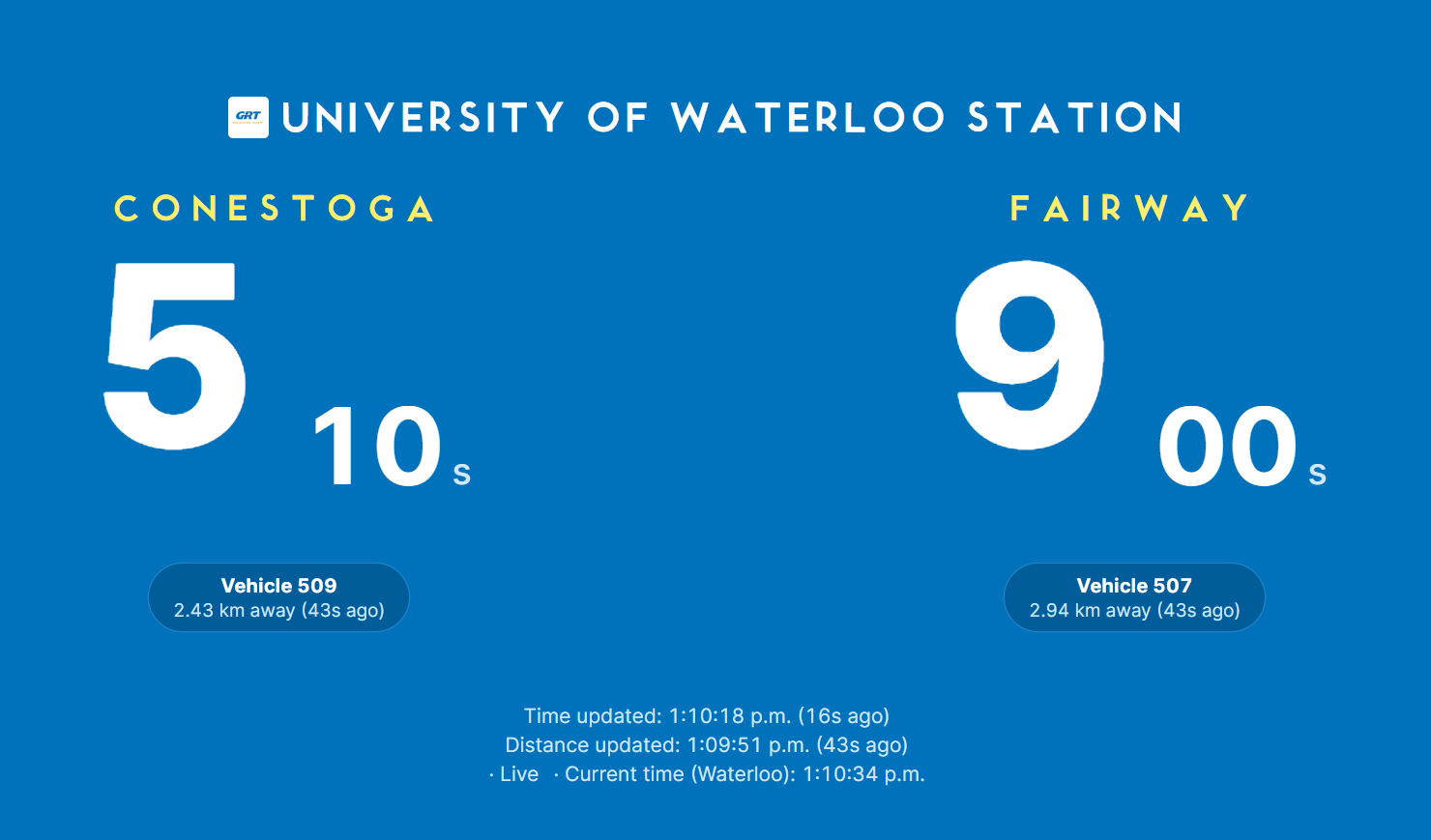

ESP32-Based Next Train Arrival Display

Cloud Infrastructure, Real-Time Transit Data & Embedded Systems Integration

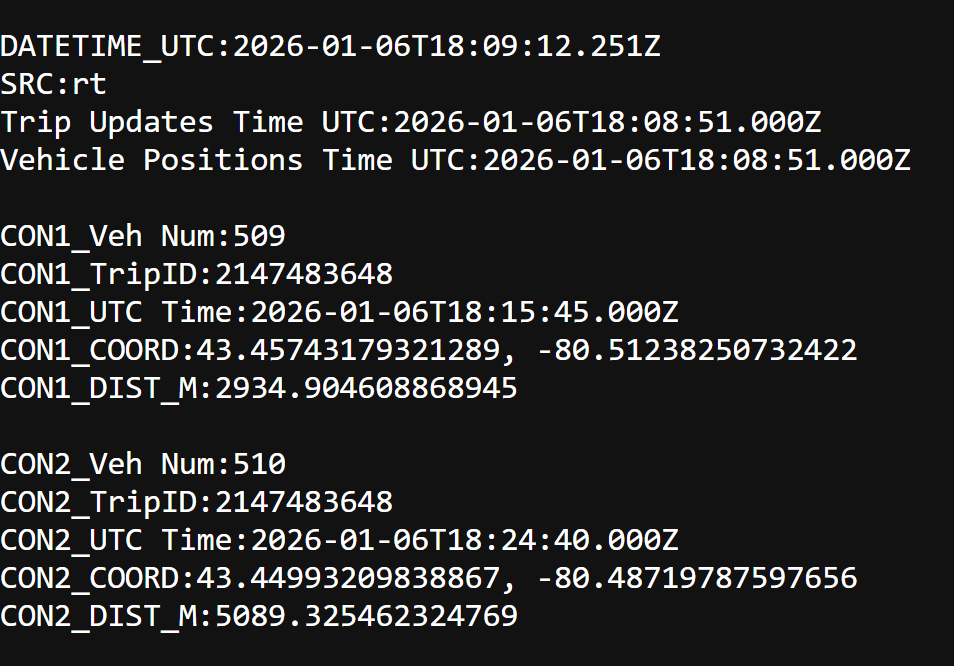

Cloudflare Worker & Backend Architecture

Designed and deployed a Cloudflare Worker to act as a lightweight backend service for retrieving real-time public transit arrival data. Implemented server-side logic to fetch and process GTFS-realtime feeds from a transit agency endpoint, handling network requests, data parsing, and response formatting within the constraints of an edge-executed environment. The Worker serves as a stable, low-latency interface between external transit data sources and embedded hardware clients.

GTFS Data Processing & API Design

Worked directly with GTFS and GTFS-realtime data formats to extract relevant arrival and schedule information from raw feed data. Identified required entities and fields within the feed and filtered the dataset to return only the information needed for downstream display, reducing payload size and complexity. Designed the Worker’s response structure to be deterministic and microcontroller-friendly, enabling straightforward parsing on an ESP32 without relying on heavyweight libraries.

Embedded Systems Integration (Ongoing)

Currently integrating the Cloudflare Worker backend with an ESP32-based display system. The embedded firmware is being developed to perform periodic HTTP requests to the Worker endpoint, synchronize timing, and prepare arrival data for real-time visualization. Ongoing work includes optimizing update intervals, handling network reliability, and designing a clear, glanceable display format suitable for transit-style information presentation.

ESP32-Based Shop Buzzer Automation

Embedded Systems & Industrial Control Integration

Embedded Firmware & Time Control

Developed an ESP32-based control system to automate shop-wide break and lunch buzzer signaling. Programmed firmware to manage scheduled events using network time synchronization, ensuring accurate timing across power cycles and system restarts. Implemented logic to handle multiple daily schedules without manual intervention.

Hardware Integration & Safety

Integrated the ESP32 with a relay-controlled industrial buzzer, isolating low-voltage control logic from higher-power signaling hardware. Designed wiring and control logic to safely interface with existing shop infrastructure while maintaining reliable actuation under repeated daily use.

Deployment & Operational Reliability

Deployed the system in a live manufacturing environment and validated consistent operation over extended use. Adjusted timing logic and system behaviour based on real shop feedback, resulting in a reliable, maintenance-free solution that eliminated manual buzzer operation and reduced scheduling errors.

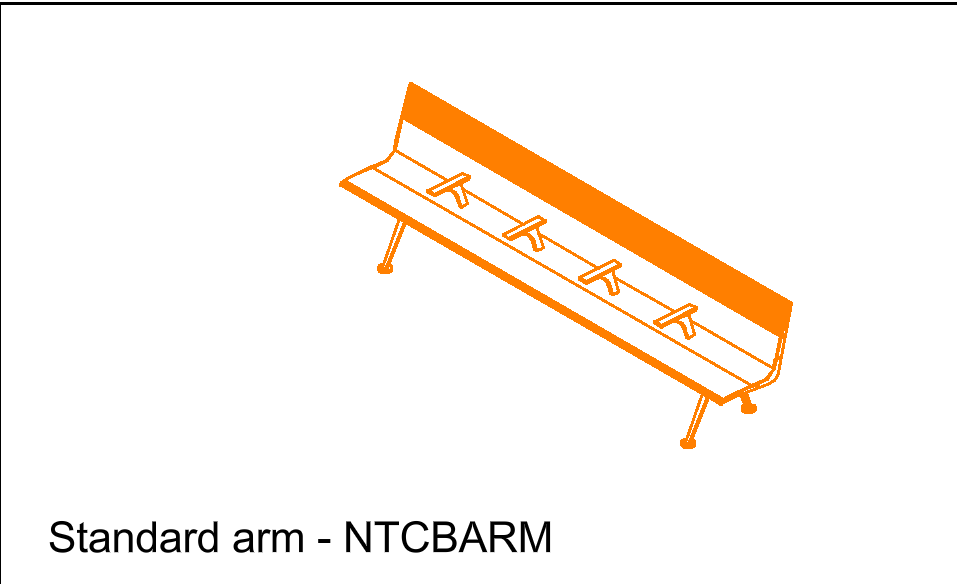

Armrest Fastener Change Validation (BIFMA)

Mechanical Testing & Compliance Risk Assessment

Test Design & Load Simulation

Designed a custom mechanical validation to assess the impact of changing armrest fasteners from M6 to M5 on an existing seating product. Interpreted the intent of BIFMA loading requirements and translated them into a practical test setup. Vertical loads were applied using calibrated weights, while lateral loads were simulated using a pulley-based system routed around the chair to replicate real-world side loading at the armrest interface.

Execution & Structural Evaluation

Executed the validation tests and monitored the armrest assembly for fastener pull-out, joint failure, and structural degradation under applied loading. The test configuration isolated the fastener interface to directly evaluate performance relative to the original design intent rather than relying on conservative assumptions.

Engineering Decision & Compliance Outcome

Based on observed performance, concluded that the M5 fasteners met functional requirements. The results supported the decision that the change did not require full BIFMA recertification, avoiding unnecessary cost and schedule impact while maintaining product integrity.

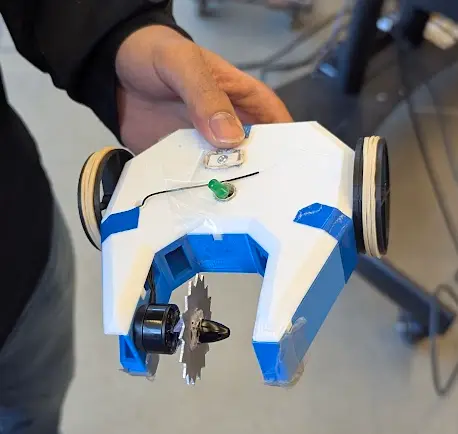

Mini BattleBot Competition — 150 g Class

Compact Mechatronic System Design & Integration

System Architecture & Constraint-Driven Design

Designed and built a fully functional 150-gram combat robot under strict mass, size, and safety constraints. The architecture prioritized minimal mass, efficient packaging, and mechanical robustness, requiring deliberate tradeoffs in component selection, layout, and structural design to remain competitive while staying within the weight limit.

This phase forced early decisions around drivetrain configuration, weapon integration, and structural geometry, with constant attention to mass budgeting and center-of-gravity management.

Electrical Integration & Control Systems

Integrated core electrical systems including brushed DC drive motors, a dedicated weapon motor, electronic speed controllers, a LiPo battery, and an RF transmitter–receiver system with an emergency stop. This project served as my first hands-on exposure to RC control systems, power distribution, and motor control at a very small scale, requiring careful wiring, signal routing, and component placement to ensure reliable operation.

Electrical subsystems were validated incrementally to isolate faults and reduce risk before full system integration.

Iteration, Packaging & Competition Readiness

Completed two full hardware iterations. The first iteration validated core electrical and control systems using an Arduino Nano mounted on a top-layer platform. The second iteration transitioned to a more compact, bottom-layer integrated layout optimized for durability, reduced wiring length, and improved mass distribution. Each revision focused on removing redundancy while preserving functionality, resulting in a robust competition-ready system despite tight constraints.

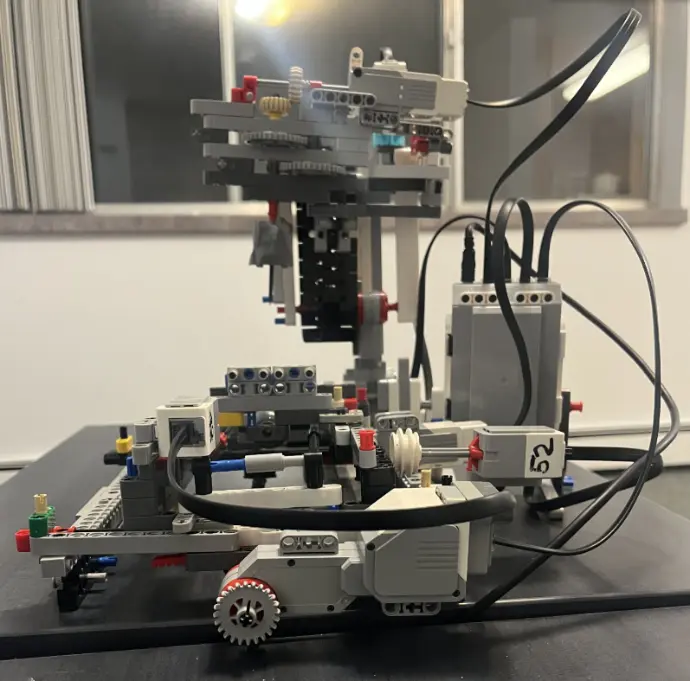

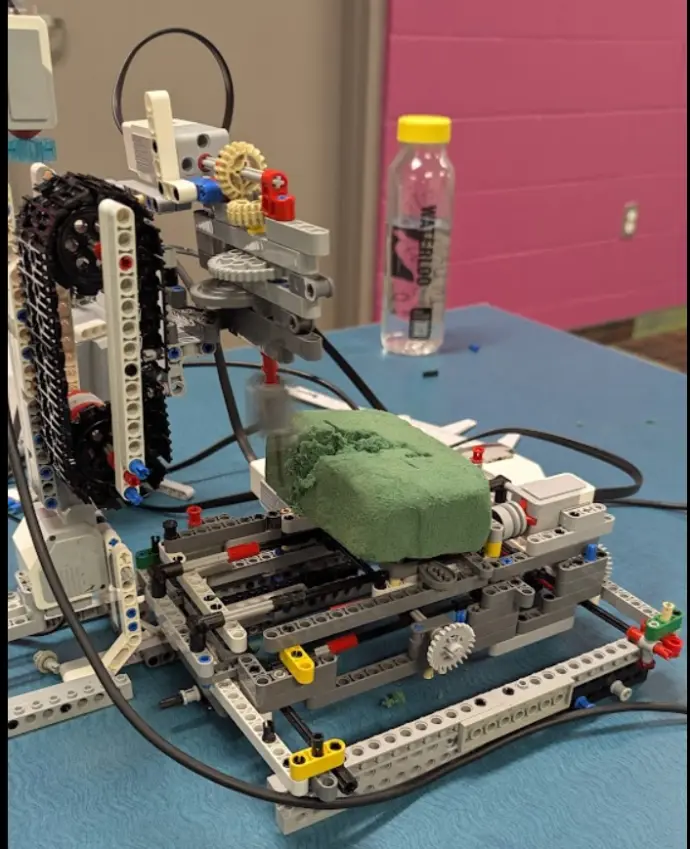

EV3-Based CNC Milling Machine

Multi-Axis Mechatronic System Design & Control

System Architecture & Mechanical Design

Co-designed a functional 3-axis CNC milling machine using LEGO EV3 components to introduce subtractive manufacturing principles in a safe, accessible format. Developed a mechanically stable architecture with independent X, Y, and Z axes using rack-and-pinion motion for planar movement and a chain-driven vertical axis for cutter control. Designed structural supports to minimize vibration while operating within strict hardware and range-of-motion constraints.

Motion Control, Sensing & Safety Logic

Implemented motion control and calibration logic in RobotC, integrating motor encoder feedback and touch sensors to establish an absolute coordinate system. Designed startup calibration routines, axis limit detection, and boundary-checking logic to prevent invalid toolpaths from exceeding mechanical limits. Implemented a hardware-interrupt emergency stop task that could immediately halt all motion regardless of program state, prioritizing safe operation.

File-Driven Toolpaths & System Validation

Developed a text-file-based instruction system to execute relative toolpath commands, enabling user-defined cuts without manual intervention. Integrated speed selection for both axis motion and cutter rotation, allowing adaptation to different cutting conditions. Validated system performance through iterative mechanical and software testing, successfully milling engraved and extruded geometries into floral foam while maintaining repeatability and operational reliability.

First Place — Waterloo Engineering Competition

Junior Design Category - Rapid Mechanical Design & Systems Integration

Problem Framing & Constraint Management

Competed in a six-hour design sprint during the Spring 2025 Waterloo Engineering Competition (Junior Design), tasked with developing a mechanical system to transport marbles uphill to a remote village without access to electricity. Interpreted strict constraints on terrain, materials, budget, and envelope size, and translated them into concrete design requirements under significant time pressure.

Concept Development & Rapid Prototyping

Developed a suspended cable-car system inspired by gondola transport, allowing payloads to travel above uneven terrain without ground contact. Selected this architecture to minimize friction, reduce sensitivity to terrain variation, and improve reliability. Built and iterated on physical prototypes rapidly, refining tensioning, alignment, and structural elements to ensure consistent operation.

Performance Optimization & Competitive Outcome

Optimized the system through testing and refinement to improve throughput and reliability while maintaining material efficiency. The final design demonstrated consistent performance within constraints and was awarded 1st place among all Junior Design teams. Selected to represent the University of Waterloo at the 2026 Ontario Engineering Competition.

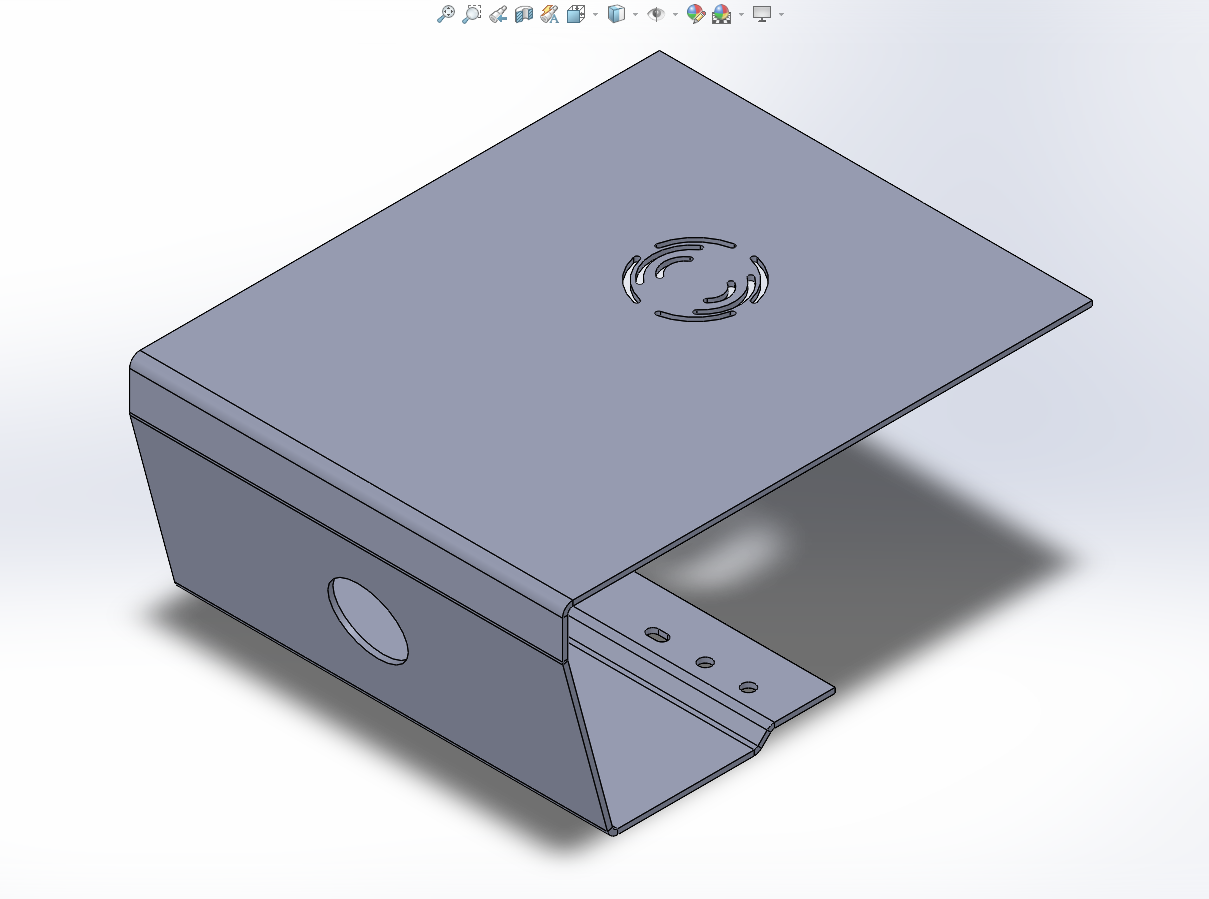

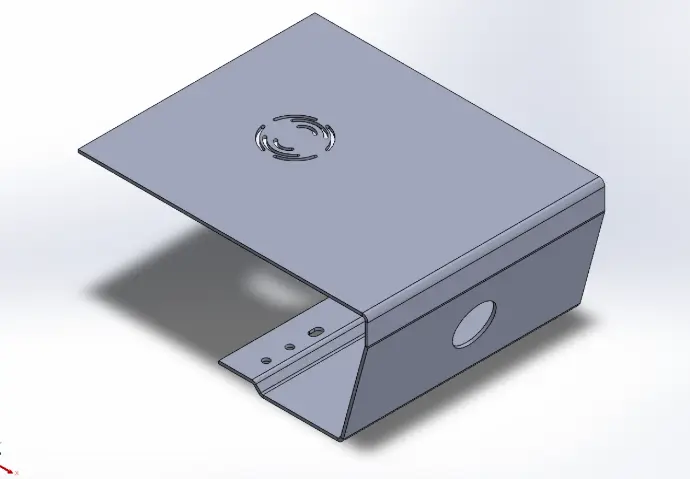

Template Holder Design

Sheet Metal Fixture Design for Manufacturing

Design Intent & Manufacturing Context

Designed a custom sheet metal template to enable precise alignment of a laser engraving tool over pre-assembled furniture at Arconas. The fixture was intended to improve repeatability and reduce setup time during engraving by providing a consistent physical reference rather than relying on manual positioning.

Sheet Metal Design & Feature Integration

Modeled the template as a formed sheet metal component, incorporating a central circular cutout to align with an existing switch feature on the table. Added a bent flange for rigidity and orientation control, along with accurately spaced mounting holes to allow secure attachment to the underside of the furniture during use.

Process Improvement & Repeatability

Enabled faster and more reliable engraving by ensuring consistent tool placement across parts, reducing variability introduced by manual alignment. The final design supported repeatable operation in a production environment, reinforcing the role of simple fixtures in improving process consistency and quality.

Laser Engraving Process Development

Manufacturing Process Optimization & Experimental Validation

Process Setup & Independent Investigation

Independently led the investigation into methods for embedding a wireless charging logo onto pre-manufactured Corian table surfaces. Researched laser engraving feasibility for solid-surface materials and set up the laser system from scratch, defining test objectives, constraints, and evaluation criteria without an existing reference process.

Parameter Testing & Iteration

Conducted structured experimentation to optimize laser parameters such as power, speed, focus height, and pass strategy. Explored alternative marking approaches, including engraving through a temporary blue plastic film layer, to improve contrast and edge definition while maintaining surface quality across Corian and Black Fenix materials.

Process Validation & Manufacturing Readiness

Validated engraving conditions that produced clean, consistent markings suitable for branding trials, and documented effective parameter ranges and material responses. Established a repeatable process that allowed the team to move forward with logo application on finished surfaces while controlling visual variation.

Custom Machined Aluminum Keychain

CAD-to-Manufacturing & Shop Fabrication Project

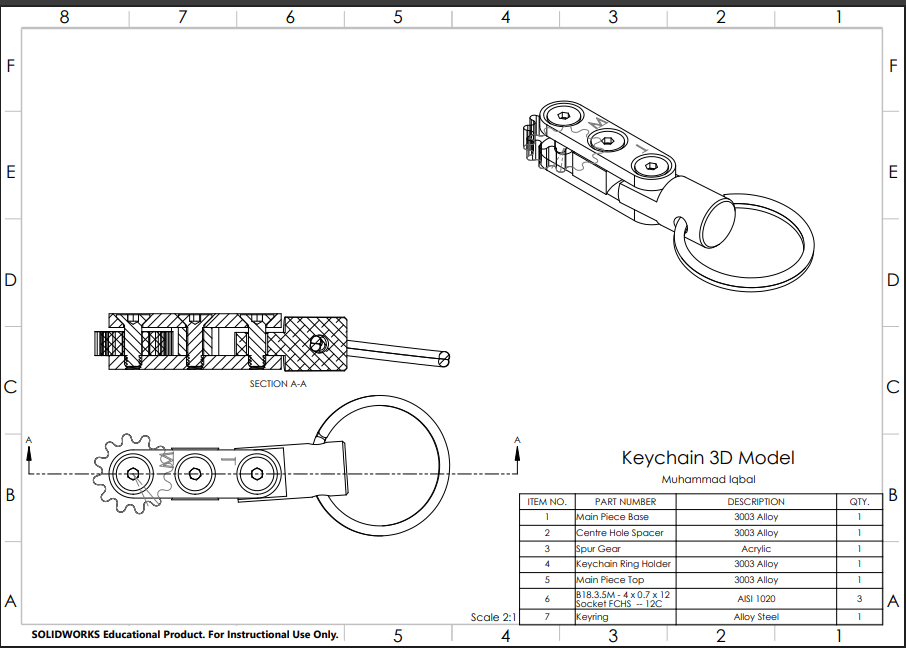

CAD Modeling & Manufacturing Planning

Designed a multi-part aluminum keychain assembly in SolidWorks, modeling individual components with appropriate clearances for assembly and motion. Generated detailed engineering drawings and planned machining steps to ensure features could be produced accurately using available shop equipment.

Machining, Tooling & Hands-On Fabrication

Fabricated all components in the campus machine shop using a combination of manual machining and CNC operations, including turning, drilling, tapping, and profiling. Selected tools, feeds, and setups to achieve proper fit between parts while maintaining surface finish and dimensional accuracy.

Fit, Finish & Quality Verification

Verified fit and finish through part inspection and iterative adjustment, ensuring smooth articulation between components. Evaluated tolerances and surface quality to produce a durable, functional assembly that now serves as both a keychain and a tactile fidget mechanism.

Personal Wireless Charger Mount

Product-Oriented CAD Design & Prototyping

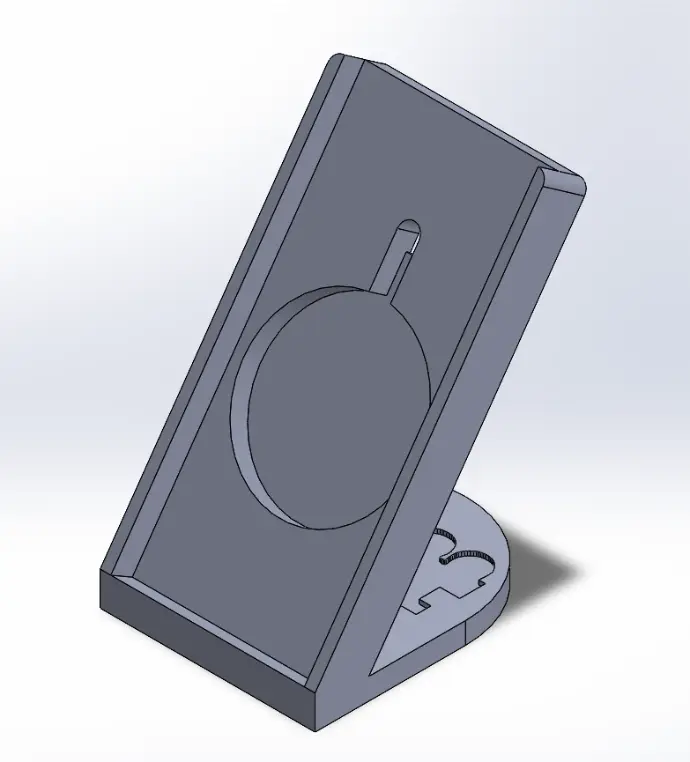

Design Intent & Requirements Definition

Designed a dedicated mounting stand for a round wireless charging pod obtained during my internship at Arconas, with the goal of creating a stable, professional-looking phone charging solution suitable for desk or customer-facing environments. Defined requirements around stability, alignment, cable management, and visual cleanliness before modeling.

CAD Modeling & Fit Optimization

Modeled the stand in CAD with a precisely dimensioned circular cutout to achieve a snug, repeatable fit for the charging pod while maintaining correct charging alignment. Incorporated appropriate wall thicknesses and angles to support the phone securely during use, balancing printability with structural rigidity.

Cable Management & Aesthetic Integration

Integrated a concealed rear cable exit to route the charging wire out of sight, preserving a clean front-facing appearance. The final design prioritized both function and presentation, demonstrating how small geometric decisions can improve usability and perceived product quality.

Steel-on-Steel Friction Testing

Mechanical Testing & Motion Analysis Project

Test Rig Design & Experimental Control

Designed and assembled a low-cost mechanical test rig to quantify kinetic friction between steel surfaces under varying contamination conditions. Selected an inclined-plane configuration to simplify force modeling, ensured repeatable geometry, and controlled surface preparation to reduce variability between trials.

Rapid Measurement & Data Extraction

Used slow-motion video capture and frame-by-frame analysis to extract displacement–time data and compute acceleration without dedicated sensors. Translated motion data into friction coefficients by isolating gravitational and frictional components, enabling quantitative analysis with minimal instrumentation.

Engineering Insight & Safety Implications

Evaluated how increasing organic contamination (pectin–water mixtures) reduced available friction between steel interfaces, directly modeling the rail “low adhesion” problem caused by leaf residue. Interpreted results in the context of braking performance, traction loss, and safety margins in rail transport systems, highlighting how small surface changes can have system-level consequences.

Arduino Speaker Synthesizer

Embedded Systems & Signal Generation Project

Embedded Programming & Signal Generation

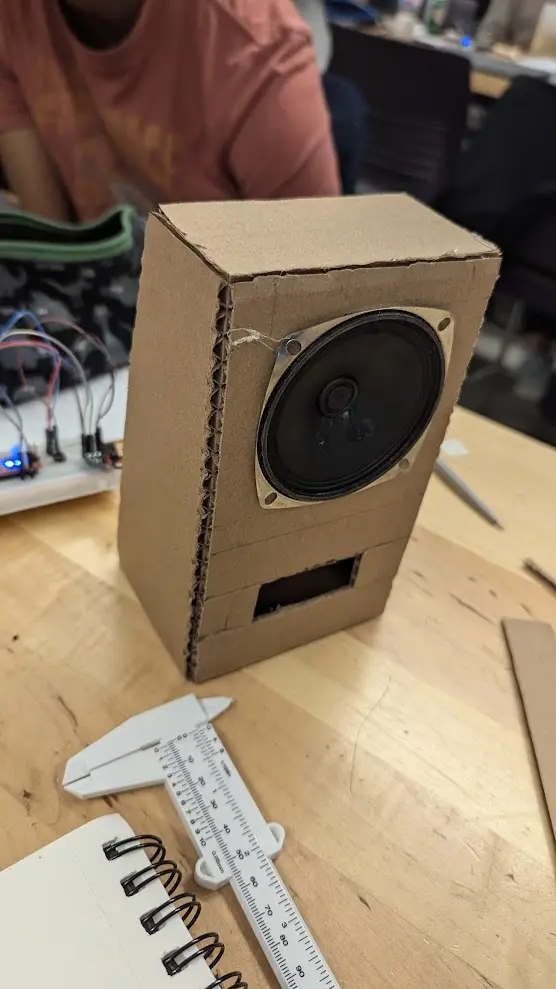

Developed an audio tone-generation system using an Arduino and the Mozzi synthesis library to generate precise frequencies corresponding to piano-like notes. Implemented waveform control and timing logic to produce stable audio output, translating digital control signals into real-time analog sound.

Hardware Integration

Integrated the microcontroller with a discrete speaker driver circuit, accounting for signal amplitude, impedance, and power limitations of the Arduino output. Validated audio clarity and pitch accuracy through iterative tuning of synthesis parameters and hardware configuration.

Enclosure Design & System Optimization

Designed and constructed a custom cardboard speaker enclosure to improve acoustic projection and resonance within rapid prototyping constraints. Evaluated enclosure geometry and material effects on sound amplification, reinforcing the role of mechanical design in system-level performance.

Hoffmann Apparatus — Electrochemical System Investigation

IB Higher Level Chemistry Internal Assessment

System Setup & Instrumentation

Built and tested a custom Hoffmann apparatus to study water electrolysis as a coupled electrical–chemical system. Integrated a variable DC power supply, current and voltage measurement, and inert electrodes, and refined electrode placement and operating conditions to improve gas separation and repeatability.

Measurement, Modeling & Verification

Measured hydrogen and oxygen production indirectly through mass change and validated results against theoretical predictions using Faraday’s laws. Analyzed how electrolyte concentration affected efficiency, identifying non-ideal behavior caused by ionic charge bypass and gas retention.

Engineering Constraints & Design Insight

Recognized practical limitations in small-scale electrochemical systems, including measurement uncertainty, side reactions, and mechanical constraints of the apparatus. Proposed design improvements to reduce losses, improve gas collection, and increase reliability, reinforcing the importance of designing for real-world constraints rather than idealized theory.

Stirling Engine — Experimental Thermodynamics Study

IB Physics Extended Essay focused on evaluating the feasibility of using Stirling engines for low-grade waste heat recovery through controlled experimentation and data analysis.

Experimental Design & Measurement

Designed a controlled test setup to analyze Stirling engine performance under varying thermal absorption conditions. Measured rotational speed decay using frame-by-frame smartphone video analysis and controlled variables including ambient temperature, heating duration, and alignment.

Data Analysis & Critical Reasoning

Processed experimental data to model angular velocity decay over time, evaluated uncertainty and sources of error, and compared performance trends across different surface conditions to draw quantitative conclusions.

Engineering Insight & Design Tradeoffs

Identified practical limitations related to heat dissipation, material heat capacity, and mechanical friction. Proposed design improvements to improve sustained operation and highlighted constraints affecting real-world waste heat recovery systems.

Contact Muhammad Iqbal

For engineering opportunities, project collaboration, or technical discussions.